Since 1978 EEI S.p.A. designs and manufactures electronic equipment for cableway systems, for the transport of people and materials.

With more than 40 years of experience in the sector, EEI with its products is able to provide the highest quality standards in terms of reliability and safety.

In these years of activity, EEI has designed and built the electronic power and control equipment of hundreds of ropeways for the transport of people and materials, from the simplest to the most complex and automated, thanks to the considerable levels of safety achieved through continuous collaboration with the main world manufacturers.

The types of automation systems for cableway installations made so far:

- Funicolars

- Aerial Tramways

- Inclined elevators

- Teleferics

- Surface lifts

- Fixed-grip chairlifts

- Detachable gondola lifts and chairlifts

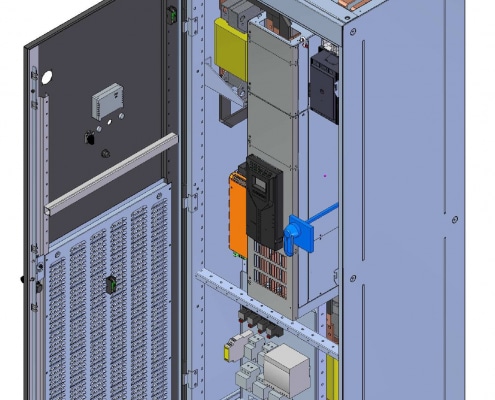

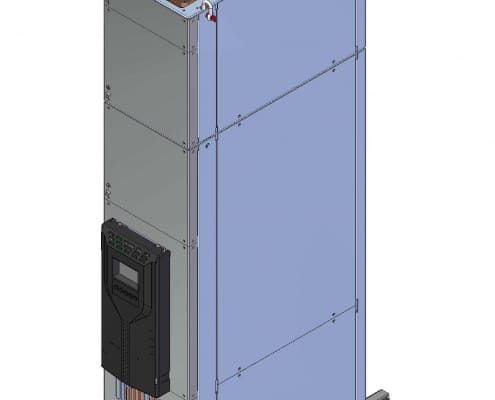

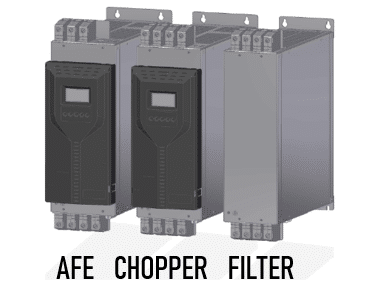

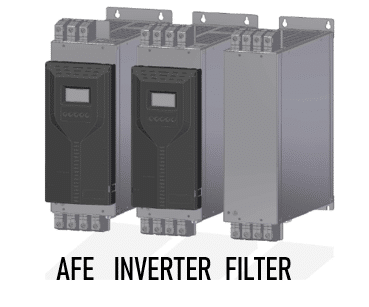

New EEI proposal for cabinets is based on book style inverter structure, allowing efficient and compact solutions.